From the precision workshops in Munich, Germany to the production bases in Monterrey, Mexico, from fabric workshops in Southeast Asia to R&D centers in North America, the pulse of manufacturing beats in unison across the globe. Our team consists of such a group of cross-cultural artisans—they speak different languages, yet interpret the meaning of “quality” with the same dedication. In the three fields of sewing, injection molding, and silicone, they have nurtured craftsmanship achievements that stand the test of the market with years of experience and innovation.

Core Belief: Craftsmanship transcends regions, standards connect the world, and every product is a crystallization of global artisans’ collaboration

1. Tacit Understanding in Stitches: Cross-Ocean Inheritance of Sewing Craftsmanship

Carlos, a 62-year-old sewing expert from Spain, has 40 years of experience in the field. His grandfather was a renowned tailor in Madrid, and having been immersed in this craft since childhood, he holds extremely strict standards for stitches—”The error in stitch spacing must not exceed 0.3 millimeters. This is respect for the fabric and responsibility to the user.” Three years ago, to meet the needs of polar outdoor clothing for the Nordic market, he led a team of members from Vietnam and Turkey to conduct repeated tests on the properties of windproof and waterproof fabrics.

Eventually, they developed the “diagonal overlocking + hot-melt reinforcement” composite process, which solved the problem of air leakage in traditional sewing. Clothing produced with this process achieved sealed protection in minus 40°C environments during tests by Arctic expedition teams. Today, the “Craftsmanship Inheritance Program” led by Carlos has trained more than 200 transnational sewing technicians, allowing precise stitching techniques to take root in workshops around the world.

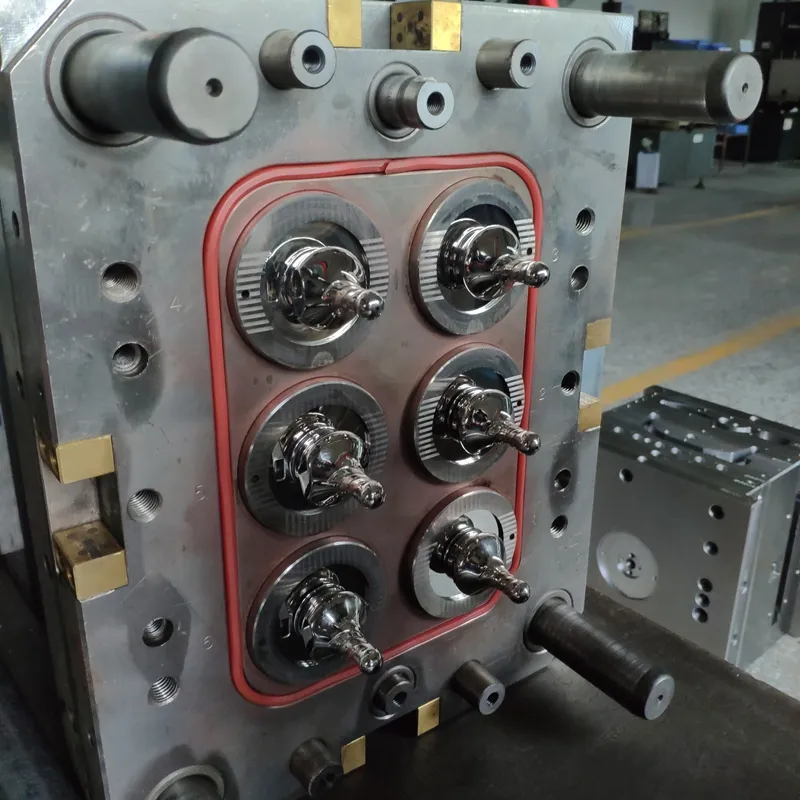

2. Precision in Molds: Global Collaboration in Injection Molding Technology

“The precision of the mold defines the quality of the product”—this is the professional creed of Kengo Takahashi, a Japanese injection molding engineer. When customizing a diagnostic instrument housing for a global medical giant, the 0.003mm dimensional tolerance requirement put forward by the client once plunged the team into a predicament. Takahashi led a R&D team composed of engineers from Germany and Taiwan, China, integrated material data from the Technical University of Munich and processing experience from Taipei mold workshops, and completed 16 process iterations over two months.

They adopted the “nano-coated mold + intelligent temperature-controlled injection molding” technology, which not only met the precision requirements but also increased production efficiency by 40%. This case later became a precision benchmark in the global injection molding industry, enabling our injection molding products to successfully enter the supply chain of high-end medical equipment in Europe and America. Today, the “Global Technology Sharing Platform” led by Takahashi allows engineers from different regions to synchronize mold R&D data in real time, shortening the technology transformation cycle.

3. Balance in Formulas: Transcontinental Innovation in Silicone Field

Emily, a 38-year-old materials science doctor from Canada, has focused on silicone formula R&D for 12 years. Her team’s most proud achievement is the high-temperature resistant silicone sealing ring developed for the new energy vehicle industry. To meet the strict battery safety standards in the North American market, she and R&D personnel from India and Brazil spent countless late nights in the Singapore laboratory.

By adjusting the ratio of nano-reinforcing agents and vulcanization curves, the “anti-aging silicone formula” they developed can work continuously at 180°C for 10 years without performance degradation, far exceeding the industry average of 5 years. This formula has not only passed the dual international certifications of UL and IEC but also been included in the core supplier system by automotive companies such as Tesla and BMW. Emily often says, “Silicone is soft, but our quality standards must be as firm as steel.”

4. Unity in Supply Chain: Global Team’s Quality Guardian

The achievement of quality never relies on a single link, but on the collaborative effort of the global supply chain. Olia, a procurement specialist from Kenya, spent half a year visiting 12 workshops in 8 countries including Ethiopia and Bangladesh to find organic fabrics that meet the EU OEKO-TEX® 100 standard. The organic cotton fabrics finally selected increased the premium rate of our sewing products in the European market by 25%.

Brian, a quality inspection supervisor from the United States, has established a “three-level sampling inspection system”—initial inspection at the production site, re-inspection at the regional level, and final inspection at the global level. Each product is equipped with a unique traceability code; by scanning the code, one can view the full-chain information such as raw material origin, production artisan, and inspection data. Last year, regarding a silicone product color difference issue reported by a European client, the traceability system located the root cause as a slight difference in dye batches within 48 hours. We quickly completed rectification and established a pre-inspection mechanism for dye batches.

In the wave of globalization, the competition in the manufacturing industry is no longer a contest between individual enterprises, but a comprehensive competition of supply chains and craftsmanship spirit. We firmly believe that regardless of skin color and language, the pursuit of quality is the common language of global artisans. In the future, we will continue to build a cross-cultural craftsmanship exchange platform, allowing the delicacy of sewing, the precision of injection molding, and the stability of silicone to shine more brilliantly in the global market. If you are looking for a manufacturing partner with both craftsmanship and international perspective, we look forward to moving forward hand in hand with you.