This article focuses on the green transformation practices of the sewing, injection molding and silicone industries, demonstrating the environmental responsibility and innovative paths of the manufacturing industry from the entire chain of raw material selection, production to recycling.

Driven by the “dual carbon” goals and the global environmental protection wave, the manufacturing industry is undergoing a profound transformation from “scale first” to “green first”. As a deep-rooted player in the field of sewing, injection molding and silicone products, we firmly believe that sustainable development is not an additional responsibility, but a core driving force for industrial upgrading. Over the years, we have integrated the concept of environmental protection throughout the entire chain, using green intelligent manufacturing as a pen to write the environmental protection answer sheet of the manufacturing industry.

Core Environmental Protection Measures

- Prioritize GRS (Global Recycled Standard) certified recycled fabrics

- Introduce energy-saving equipment, reducing energy consumption by over 30%

- Scrap utilization rate reaches over 95%

Typical Application Cases

- Recycled polyester fabric → Outdoor storage bags

- Recycled cotton → Home textile products

- Plant dyes → Environmental protection clothing accessories

Sewing Process: From “Fabric” to “Finished Product”, Weaving a Low-Carbon Textile Ecosystem

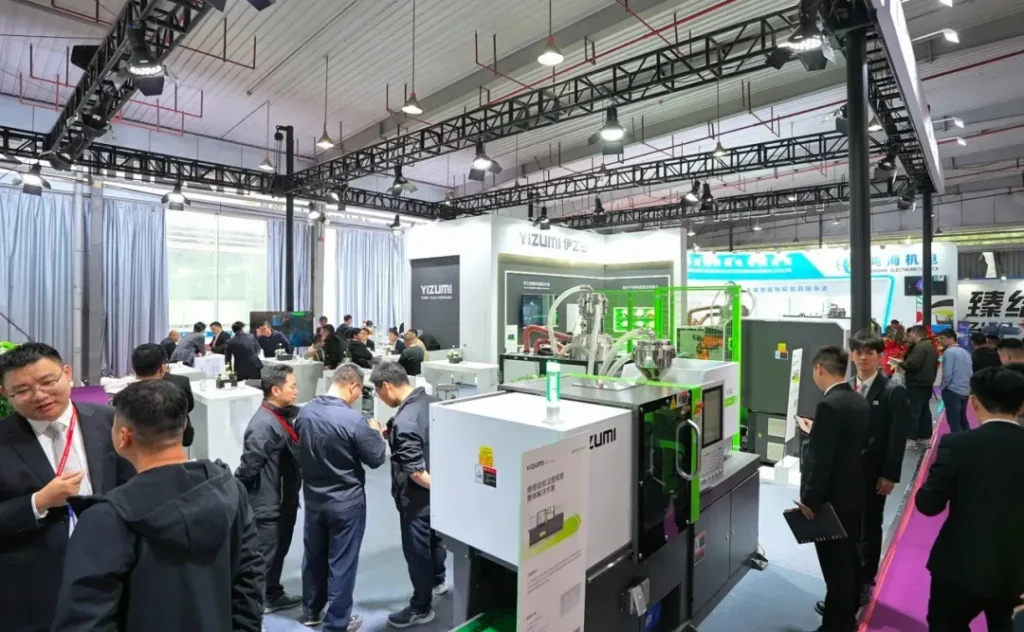

Three Major Breakthroughs in Injection Molding Environmental Protection: Raw Material Upgrade (Biobased/Degradable Plastics), Equipment Innovation (Servo Energy-Saving Injection Molding Machines), Process Optimization (Waste Recycling)

Green Transformation of Production End

- Servo energy-saving injection molding machines, reducing unit energy consumption by 40%

- “Activated Carbon + Photocatalysis” waste gas treatment, VOCs purification rate over 98%

- Optimize parameters, raw material utilization rate reaches 98%

Construction of Circular System

- Recycle waste injection molding products

- Crush and process into recycled materials

- Used for producing low-precision structural components

Injection Molding Process: Focusing on “Emission Reduction” to Build an Efficient and Environmental Protection Molding System

Silicone itself has environmental protection characteristics such as recyclability and high temperature resistance. We maximize its advantages through technological innovation to build a safe and environmentally friendly product system.

Raw Materials and Standards

- Food-grade/medical-grade silicone raw materials

- Compliant with EU REACH and China GB 4806 standards

- Free of harmful additives such as phthalates

Processes and Applications

- Low-temperature and low-pressure vulcanization, reducing energy consumption by 25%

- Closed-loop recycling of silicone scraps

- Environmental protection seals → New energy vehicles/energy storage equipment

Silicone Process: Empowering with “Characteristics” to Build a Safe and Environmental Protection Product Matrix

Green manufacturing is a system engineering involving the entire industrial chain. We not only practice environmental protection ourselves, but also promote the coordinated development of upstream and downstream partners to form a sustainable industrial ecology.

Corporate Honors: “Environmental Protection Demonstration Enterprise”, “Low-Carbon Manufacturing Pioneer” Customer Feedback: After adopting our environmental protection accessories, the products have successfully passed the overseas environmental protection certification, and their international competitiveness has been significantly improved.

Implementation of Green Concept: From Corporate Responsibility to Industry Resonance

In the future, we will continue to increase investment in green technology R&D, explore the in-depth integration of processes and environmental protection concepts, and look forward to working with more enterprises that focus on environmental protection. With green intelligent manufacturing as the link, we will jointly promote the sustainable development of the manufacturing industry and contribute to the global home. If you have needs for environmental protection sewing, injection molding and silicone products, please feel free to contact us!