In modern manufacturing, innovation and efficiency are the two key factors driving the industry forward. How can companies effectively combine these elements to produce high-quality products? Sewing, injection molding, and silicone technologies, as three important manufacturing processes, play a crucial role in production and have driven technological advancements and product innovations across various industries. As a company specializing in these three technologies, we will take you through an in-depth exploration of these processes and their applications and benefits across different sectors.

1. Sewing Technology: Precise and Flexible Solutions

Sewing technology is widely used in industries such as apparel, home goods, and industrial fabrics. It is not only an ancient craft but, with technological advancements, sewing equipment and techniques have been innovated to breathe new life into this process.

- Precision and Flexibility

Modern sewing technology uses computer-controlled systems to precisely regulate stitch length, speed, and fabric movement, ensuring every stitch is optimal. Whether dealing with intricate designs or large-scale production, consistency and efficiency are guaranteed. - Wide Application Range

Sewing is not just used in the garment industry but is also widely applied in home products (such as curtains, sofa covers, bedding), automotive interiors, and industrial filters. When combined with other processes, sewing technology can lead to richer designs and multifunctional products. - Sustainability

As environmental awareness increases, many manufacturers are using recyclable materials and eco-friendly sewing threads to reduce resource waste and pollution in the production process. This trend brings both challenges and opportunities to sewing technology.

2. Injection Molding: High Efficiency for Large-Scale Production

Injection molding is a process where melted plastic materials are injected into a mold and cooled to obtain the desired shape. This process offers high efficiency, low cost, and high precision, making it widely used in industries like automotive, electronics, home appliances, and medical devices.

- High Production Efficiency and Precision

Injection molding can produce high-precision components in a very short time. Compared to traditional manual or other processes, injection molding offers faster production speeds while maintaining consistency, which is crucial for mass production. - Possibility of Complex Designs

Unlike traditional mechanical processing, injection molding allows for more complex product shapes, such as detailed casings or components with internal threads, meeting high-demand design requirements. - Material Diversity

Injection molding supports the use of various plastic materials, such as ABS, polypropylene (PP), and polyethylene (PE), each with distinct physical properties to meet different application needs. - Cost Advantage

The initial design and manufacturing of molds for injection molding can be costly. However, once the molds are completed, the production costs decrease significantly, making this process especially suitable for large-scale manufacturing. This is why injection molding is the preferred process in many industries.

3. Silicone Technology: Innovation and Flexibility Combined

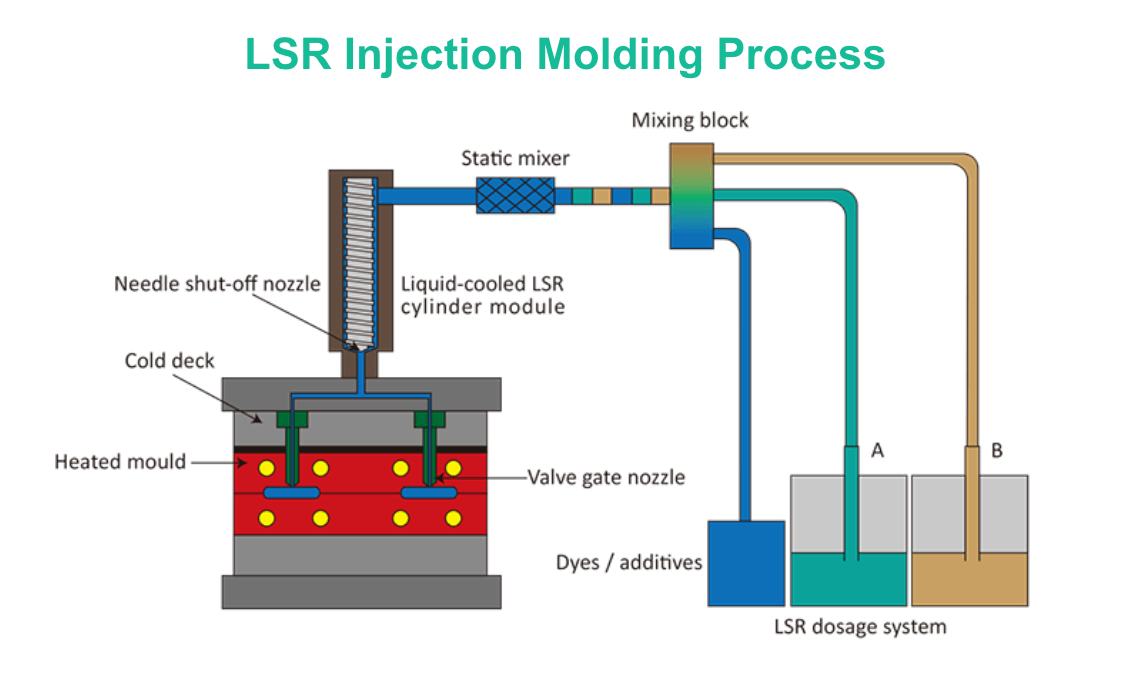

Silicone materials are widely used in various fields due to their excellent properties such as high temperature resistance, corrosion resistance, and durability. They are particularly common in consumer electronics, automotive, and medical devices. Silicone technology generally includes injection molding, compression molding, and liquid silicone molding processes.

- Flexible Molding Methods

Silicone molding techniques can be selected based on product complexity and application requirements. For example, injection molding can rapidly produce large quantities of identical silicone parts, while liquid silicone molding (LIM) is ideal for producing intricate and fine silicone products. - Durability and Safety

Silicone is a non-toxic, harmless material that is widely used in medical and food industries. It can withstand extreme temperatures and maintain flexibility and durability, without aging or degrading over time. - Diverse Applications

Silicone technology is widely applied in many sectors. In consumer electronics, silicone is used for seals, waterproof gaskets, and even external protective shells. In the automotive industry, silicone can be used for sealing gaskets and sensor protection. - Environmental Friendliness

Due to its environmentally friendly properties, silicone is a recyclable and reusable material. Additionally, waste and by-products from production can be reduced, leading to less environmental impact. Therefore, silicone technology is regarded as a green manufacturing process.

4. Integrated Applications and Industry Trends

In many industries, sewing, injection molding, and silicone technologies are often combined to achieve more efficient and precise production. For instance, in smart home devices, a combination of sewing (for fabric covers), injection molding (for plastic casings and internal parts), and silicone (for buttons, seals, etc.) may be used.

In the future, with the continuous advancement of technology, these processes will continue to evolve. With the aid of smart manufacturing, automation, and 3D printing technologies, the production modes of sewing, injection molding, and silicone technologies will become more flexible, efficient, and personalized. Moreover, environmental sustainability will become an increasingly important direction for these processes, driving more green manufacturing and innovative design.

5. Conclusion

As industry demands become more diverse, sewing, injection molding, and silicone technologies will continue to lead the way in innovation within the manufacturing sector. When choosing manufacturing processes, companies should consider their product characteristics, market needs, and cost efficiency to make the best decision. By continuously optimizing production processes, businesses can not only improve product quality and production efficiency but also gain a significant competitive advantage.

As a company, we are committed to integrating these advanced manufacturing processes and providing innovative solutions to help our clients achieve higher-quality products and faster market response.