The COVID-19 pandemic exposed the fragility of global manufacturing supply chains: sewing workshops faced fabric shortages due to port congestion, injection molding plants struggled with skyrocketing prices of plastic resins, and silicone suppliers encountered labor shortages. As the world enters the post-pandemic era, “resilience” has become a core competitive advantage for manufacturers. The value dimension of sewing, injection molding, and silicone—three fundamental processes—has expanded from mere “production efficiency” to building adaptive capabilities that “resist supply chain shocks, respond to demand fluctuations, and mitigate geopolitical risks.”

I. Three Core Dimensions of Resilient Craftsmanship

Resilient craftsmanship is built on three interconnected pillars: supply chain flexibility, process adaptability, and demand responsiveness. Unlike the traditional “just-in-time production” model that pursues extreme cost control, this new paradigm strikes a balance between efficiency and redundancy, enabling manufacturers to pivot quickly when crises arise.

For the sewing process, resilience means balancing “diversified fabric sourcing” with “quality stability”; for injection molding, the core lies in optimizing formulations to adapt to alternative resins; and for silicone processing, it requires flexible production lines capable of “rapid switching between medical-grade and consumer-grade products.” Together, these capabilities transform potential crises into opportunities for market expansion.

II. Practical Strategies for Building Resilience by Process

The three core processes face unique risk challenges—from fluctuations in raw material prices to differences in labor dependency. Practices of industry-leading enterprises show that targeted technological innovation and process adjustments are key to building process-specific resilience.

2.1 Sewing Process: Modular Production and Diversified Fabric Sourcing

The biggest pain points in the sewing industry are “single-source raw materials” and “rigid production layouts.” Leading apparel manufacturers have addressed these issues through two innovations: modular sewing workstations and digital fabric databases.

Modular workstations equipped with “quick-change bobbins” and “adjustable sewing heads” can reduce the time required to switch between clothing styles from the traditional 2 hours to less than 30 minutes. This flexibility allows factories to quickly take on urgent orders for medical protective suits or casual wear in response to demand fluctuations. Meanwhile, digital fabric databases store technical parameters (such as tensile strength and shrinkage rate) for over 50 alternative fabrics; when primary cotton supplies are delayed, AI can instantly match and recommend suitable substitutes like recycled polyester or linen blends.

After adopting these strategies, a European fashion manufacturer reduced order delivery delays by 68% during the 2022 European energy crisis. Additionally, its flexible fabric solutions helped it successfully tap into niche sustainable fashion brand clients, growing its customer base by 25%.

2.2 Injection Molding Process: Material Substitution and Energy Independence

Resilience challenges for injection molding focus on two areas: price volatility of petrochemical-based raw materials and energy dependence. Solutions lie in material innovation and the integration of renewable energy.

Material scientists have developed “adaptive resin formulations” that use AI to adjust additive ratios, addressing supply shortages of primary resins like ABS. When polypropylene prices surged by 40% in 2023, an automotive parts enterprise used this technology to replace 30% of polypropylene with rice husk-reinforced bioplastics, maintaining product strength while reducing material costs by 18%.

Energy resilience is achieved through “on-site solar energy + energy storage systems.” A U.S. injection molding enterprise installed a 500kW solar array and supporting energy storage equipment, which can meet 70% of its energy needs when extreme weather disrupts the power grid. This not only ensures production continuity but also enables the enterprise to qualify for government tax incentives for renewable energy adoption.

2.3 Silicone Process: Agile Scheduling and Quality Stability

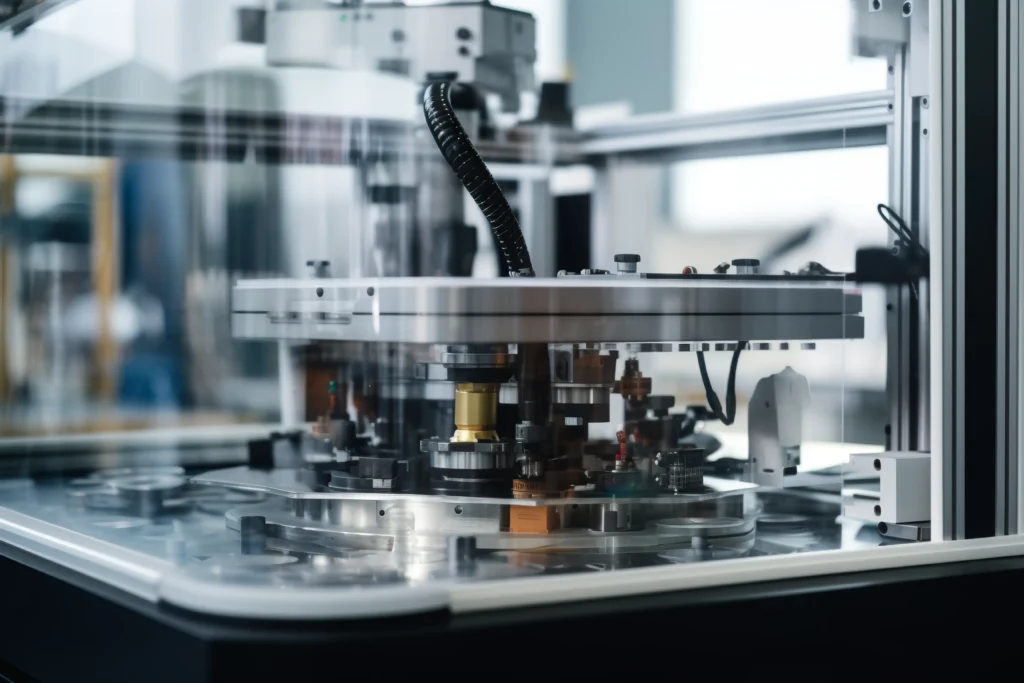

Resilience challenges in silicone processing are unique: long curing cycles and strict quality requirements in industries such as medical and automotive. Agile scheduling software and real-time quality monitoring technology have become key solutions.

Cloud-based scheduling systems integrate data from silicone mixers, curing ovens, and logistics to dynamically adjust order priorities. During an influenza outbreak, a German silicone enterprise received an urgent order from a medical client for 100,000 silicone mask seals. Using the platform’s bottleneck simulation and process adjustment capabilities, it redirected 30% of its consumer-grade production capacity to medical orders within 24 hours.

In-line sensors monitor silicone viscosity and curing degree in real time, reducing scrap rates by 40% during material switches. Even when using alternative silicone raw materials, products still meet FDA and ISO standards, avoiding high rework costs.

III. Case Study: Resilience Transformation of a Global Electronics Enterprise

A Fortune 500 electronics enterprise specializing in wearable devices once faced a 3-month production shutdown in 2021 due to chip and material shortages. Since then, it has launched a resilience transformation across its entire sewing, injection molding, and silicone processing chains.

In the production of silicone wristbands, the enterprise shifted from a single Asian supplier to a cooperative model with three regional suppliers, ensuring a 90-day raw material inventory while signing flexible pricing agreements. Its injection molding team developed universal housing molds compatible with 8 different resins, completely solving the mold modification cost issue during material shortages. In the sewing workshop, automated guided vehicles (AGVs) replaced fixed conveyors, reducing production line reconfiguration time to 45 minutes and meeting the production needs of wristbands for different devices.

The transformation yielded remarkable results: when global supply chains fluctuated again due to geopolitical conflicts in 2023, the enterprise controlled production downtime to within 48 hours—80% shorter than the industry average. Meanwhile, its rapid response capability helped it secure an exclusive OEM order from a well-known sports brand, driving 32% annual revenue growth.